Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Brand: Ruijin

Place Of Origin: China

Conductor Material: Copper, Aluminum

Packaging: Carton + Plywood case + Pallet

Productivity: 100000pcs

Transportation: Ocean,Air

Place of Origin: Taizhou ,China.

Supply Ability: 100000pcs

Certificate: ISO9001

HS Code: 7312900000

Port: Shanghai Port,Ningbo Port,China

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW

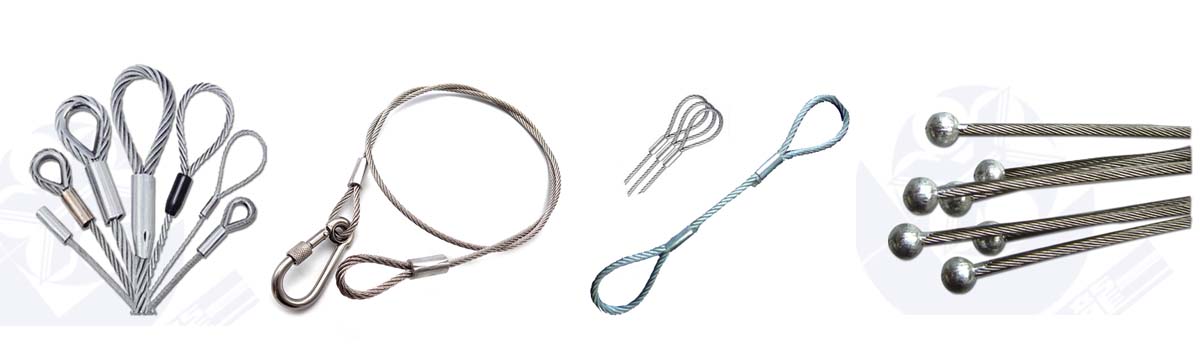

Wire rope sling manufacturing is an industry specializing in the production of wire ropes and related accessories. These products are widely used in various industries such as construction, shipping, mining, power, transportation, etc.

The main steps in wire rope sling manufacturing include:

1. Steel wire selection: Select the appropriate steel wire material according to the usage environment and requirements of the Steel Wire Rope. Commonly used ones include carbon steel wire, Stainless Steel Wire, galvanized steel wire, etc.

2. Steel wire braiding: Steel wires are braided into steel wire ropes according to certain rules. Common braiding methods include single-strand braiding, multi-strand braiding, winding braiding, etc.

3. Rigging manufacturing: Assemble wire ropes and various accessories (such as hooks, rings, clips, etc.) into rigging as needed.

4. Surface treatment: In order to improve the corrosion resistance and wear resistance of the steel wire rope, the steel wire rope is usually surface treated, such as galvanizing, plastic coating, etc.

5. Inspection testing: Conduct various performance tests on the finished Steel Wire Rope Slings, such as tensile strength test, fatigue test, corrosion test, etc., to ensure that its quality meets standards.

6. Packaging and transportation: Pack the qualified wire rope ropes and then transport them.

Wire rope sling manufacturing is an industry with high technical requirements and requires professional equipment and technical personnel. At the same time, since the use environments and requirements of Wire Rope Slings vary, the manufacturing process needs to be adjusted and optimized according to specific conditions.

Product Categories : Wire Rope Slings > Wire Rope Slings For Lamp

Home > Products > Wire Rope Slings > Wire Rope Slings For Lamp > wire rope sling fabrication

Send Inquiry

Mr. Steven

Tel:+86-523-83786100

Fax:86-523-83782808

Mobile Phone:+8613961004558

Email:jsxhyxm@163.com

Address:DongBei , Dainan Town, Xinghua, Taizhou, Jiangsu

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.